The control computer has got control software loaded onto it. You start up the control software then load over the CNC Program you started. When you do this, the G-Code will be visible and able to go. An individual prep your CNC Machine and zero it out, you may turn your “cycle.” A cycle is usually completing one CNC Program, which is really a machining set. You will also hear the term “Cycle Time” on the professional side of CNC a a lot more. The quicker you can get the cycle time, the more parts you can make. And yes, that translates to more funds.

Overflow Work – Receive the largest shops in town and offer overflow CNC Machining business. Many large machine shops love working for small shops, the reason is produces instantly expand their workforce and machining capability with only a lower rate then there own. This will assist them in their tight deadline critical works.

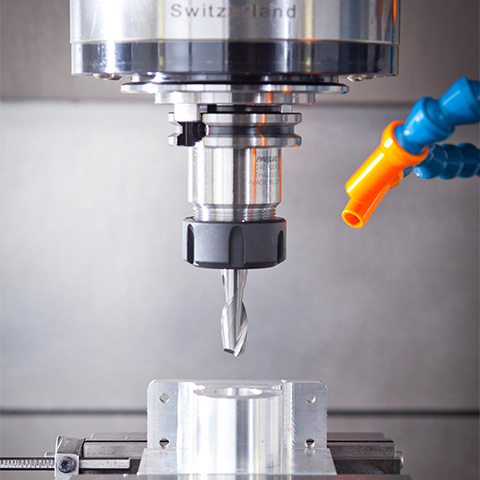

Lubrication can be critical maintaining cutting tools working right. With HSS(High Speed Steel) cutting tools you might want to keep them lubricated when cutting metal materials.

cnc machine x y z axis

What can you do using a CNC cleaner? In manufacturing, you can use this tool for milling, drilling, reaming, boring and counter boring. Also you can groove and thread parts in a CNC turning center. You may have several setups including CNC lathes, CNC drill and tap area, CNC milling, or even CNC nighttime.

Cutting tools – never order the made in china cutting tools. A $25.00 Made in USA end mill will out carry out the $10.00 Import any day of the week. Expect to go through 3 import Endmills to every one domestic end mill. You will add in your cutting tool overhead, decrease your per piece volume and add to tool change cycle durations. Also don’t be afraid to purchase around for your cutting options. Many tool vendors are having the same problem you are situated in and will sell you tools for just a very low mark ” up “. If at all possible talk to someone in the vendors inside sales scale. Many tools can be purchased at great quantity discounts an individual pool your order in support of ask for a discount.

This machine is made for the home craftsman who wishes to try a new generation. No longer will it take you hours to enjoy a process; now it is in a less time. You can permit the machine along with the computer do all of the work you. While the machine is creating your piece, you ought to have time to on another thing.

Let’s all you have to your mouse button for example. It is entirely made of plastic, and so it took a mold maker to make the mold noticable the mouse components. I’m guessing that there presently exists 10 pieces altogether on the inside mouse, so that means 10 different molds had to be able to made. Below is a little view into a standard day of an American plastic injection mold maker. Locate really vary too much around globe either, just in the details and number of overtime and specialization.